We are a company specialized in the forging of light alloys, part of the Wössner GmbH, a well-established manufacturer of special pistons based in Germany.

FORGING GROUP MONALE

Who we are

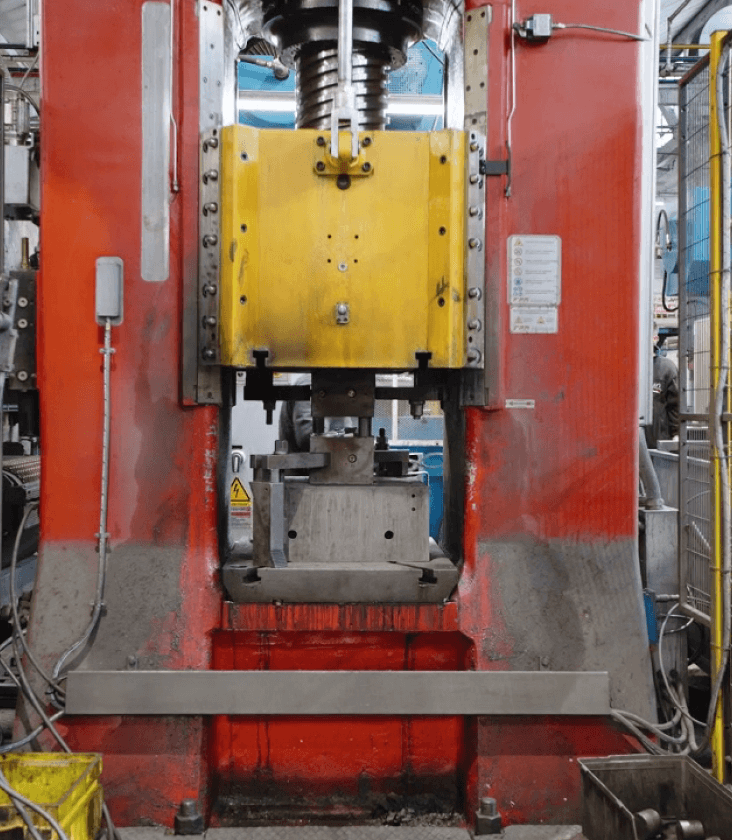

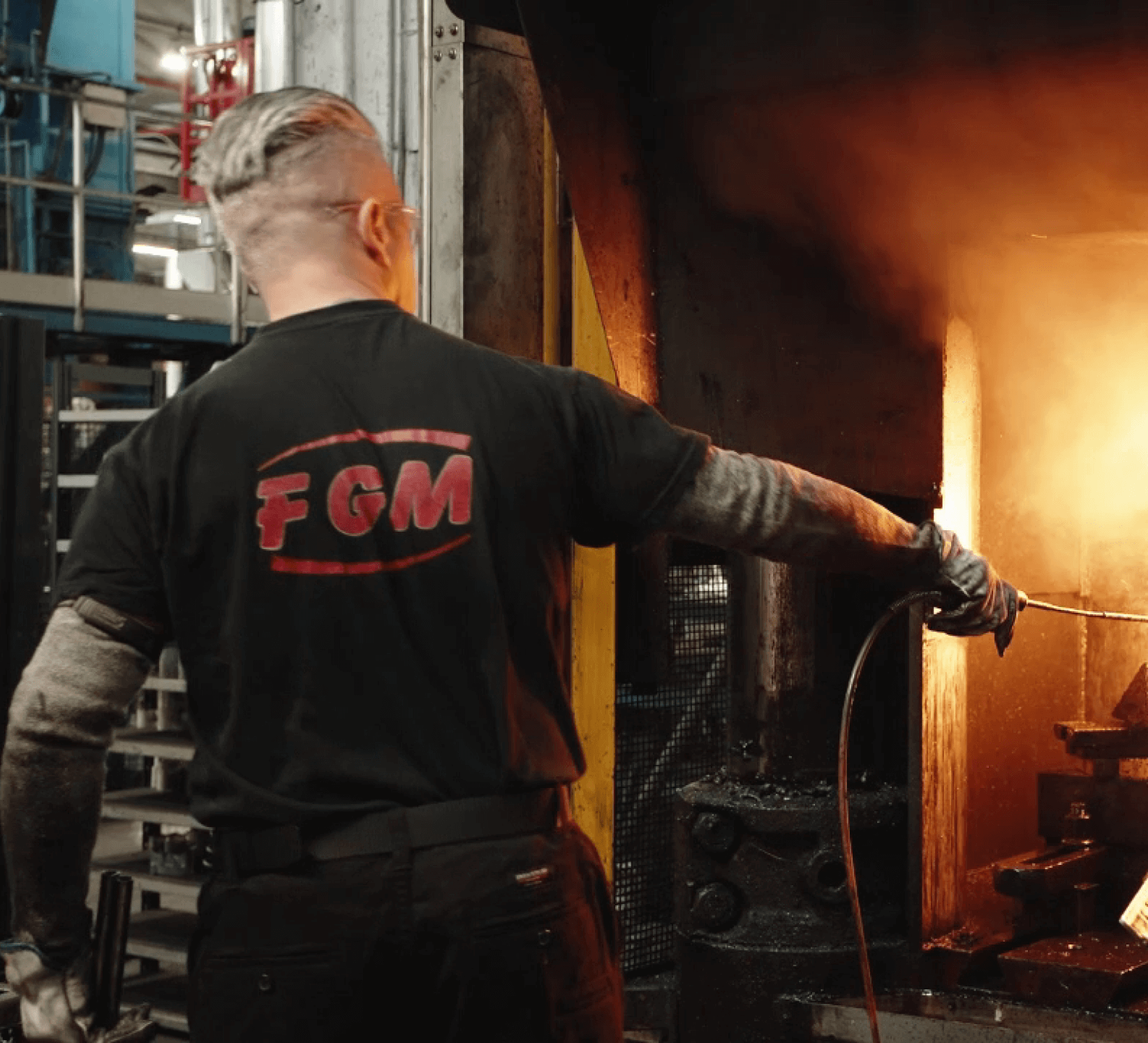

Forging Group Monale (FGM) was established in 2009 from the legacy of the historic Officine Meccaniche Sangrato, inheriting a tradition of excellence in forging and transforming it into an innovative industrial enterprise. With a special focus on aluminum alloys, FGM quickly established itself as a leader in the production of forged components, particularly pistons, a sector where quality and precision are paramount.

Our History

Offering a unique product in the market

Especially for those who require small production quantities, we always strive to create a trusted partnership with the customer. We aim to realize projects in continuous collaboration by reducing lead times, ensuring high-quality forged products with not excessively large shipping batches. We accept all projects within our capacity, being responsive to meet customer needs and taking great care of them, maintaining a human and personalized approach.

Discover

Our Values

Responsiveness

Thanks to our optimized production capacity, we can quickly handle small batches and customized orders.

Quality

The precision of our processes and attention to detail allow us to ensure products of the highest quality.

Versatility

We are able to quickly adapt to customer needs, offering tailored solutions and ongoing support.

Innovation

Our Research and Development department allows us to continuously improve processes and develop new technologies to stay at the forefront.

These values are at the heart of our identity and our success.

Products and Services

FGM offers a comprehensive range of services for every client project, including:

All our raw materials are certified, securely stored, and cut in-house.

FGM is equipped with furnaces for heat treatment during the production cycle.

FGM is equipped with a fully automated pickling system for final treatments.

Certified Company

Social Responsibility

FGM is committed to sustainability, a fundamental aspect in today’s world in which we want to continue investing. The ISO 9001, ISO 14001, and ISO 45001 certifications demonstrate our commitment to quality, environmental management, health, and workplace safety.

Quality over Quantity

A highly diversified clientele, both national and international, including companies of various sizes that require series production, prototypes, and samples. Over the years, the demand for higher quality products to be delivered in increasingly shorter times has grown.

Our Approach

Our approach has evolved to foster collaboration with clients, aiming to achieve the best possible results together. Recently, we have intensified our Research and Development (R&D) efforts with select clients.